Home › Forums › Yamaha Bikes › Yamaha Bikes › XTZ 660 Tenere Cush drive hub modification

This topic contains 11 replies, has 0 voices, and was last updated by David Thornton 12 years, 8 months ago.

-

AuthorPosts

-

February 13, 2013 at 12:39 am #102391

HI TB I notice on the ADV sight you have mentioned that you have fitted that extra bearing to the cush drive on the Tenere . My question is did you have the wheel hub unlaced or is it possible to have the job carried out as a complet wheel unit . Thanks Choot.

February 13, 2013 at 2:02 am #236647Choot, you just need the actual cush hub. So pull the wheel, pull the cush hub out. Then take the sprocket off. Send the cush hub like that with the bearings in it to Tekniks and Nick will mod it, fit new bearings and seal, mod the centre boss and happy days

Teknik contact details

47322636

TB

February 13, 2013 at 10:04 am #236648Thats great , thank’s I thought the bearing was installed in the main hub Ill now get on to it .

ChootFebruary 13, 2013 at 10:19 am #236685Welcome Choot, seems to make a huge difference the modified one in in the ADV “X” one at the moment and shows no wear for all its use.

TB

March 14, 2013 at 3:59 am #236686July 8, 2013 at 9:58 pm #236649Below is my recent experience with the cush drive dual bearing mod.

Please note:

My cush drive modification was NOT performed by Teknik and I hold no one but myself responsible for the ensuing damage and accept all responsibility for having given the mod a try.The is only my personal experience and posted for those considering the mod.

My cush drive was modified to the exact specs as noted in TB’s video by a fully qualified mechanic who also has his own extensive mechanical engineering equipment and long experience using it.

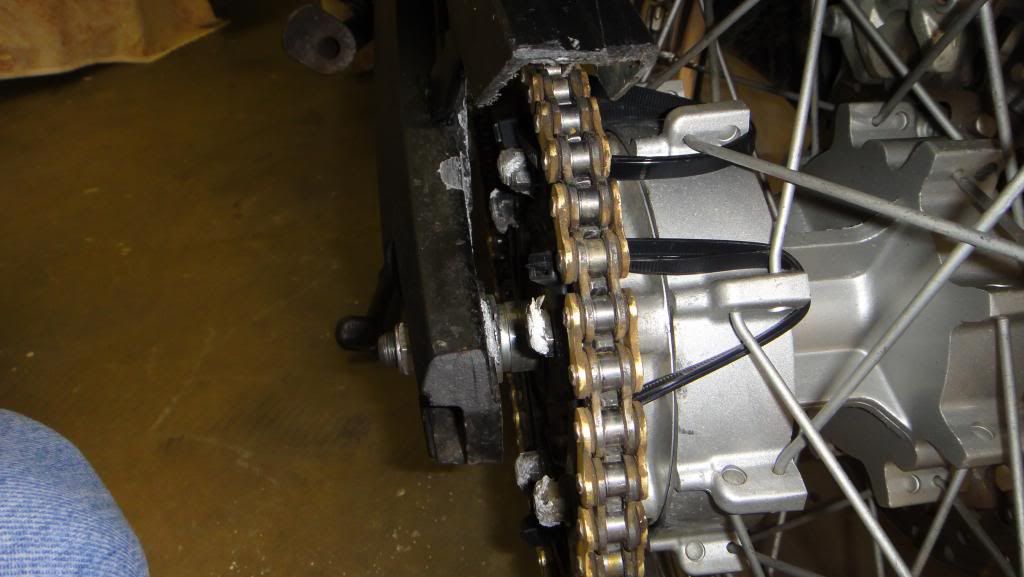

As the machining into the hub requires removal of an extra 15mm of the cush hub inner to accomodate the second bearing it leaves the inside bearing retaining surface considerably thinner.

On a recent ride (first one since the mod was performed), the remaining inner cush hub bearing retaining surface broke away from the hub, allowing the hub and sprocket to move over and chew through the swingarm.

You might well think you would hear such a racket, but as I was going pretty hard at it racing a mate for the last 20 klms of windy trail on The Rocky River Road, I didn’t hear a thing. It was only when we got to the bitchy that I noticed some take up noise when changing gears and accelerating.

Upon arrival at the servo in Tenterfield I was rather shocked to see the swingram chewed out and the damage to the hub.

After removing the rear wheel and investigating, the inner bearing retaining surface of the hub was found to be broken away completely.

After cable tieing the cush drive hub to the wheel hub I managed to ride all the way back to Boonah even managing a 100 kph all the way up the Mt Lindsay Rd and riding across White Swamp Rd. A few of the 7.6 mm cable ties broke but enough remained to hold it together till home.

Anyway after now finding a 2nd hand swingarm and sourcing a new genuine hub and attached bits (backorder from Japan), all will be good and I will leave the new cush drive unmodified.

The total bill for the damage will be just under $700, and thanks to Will at Team Moto Moorooka for the discount on new parts.

This post is not aimed at criticising TB, Nik at Teknik or anyone else. I always except all responsibility for any mod I perform on my bikes and learn from the good and bad.

This is just my experience and posted to show what may or may not happen if you perform the mod.

Dave

July 8, 2013 at 10:25 pm #245773Thanks for the feedback Dave. We learnt early in the process that the remaining retaining sleeve material couldn’t handle having a bearing hit hard against it or pressed together without extra care. It’s fine on the bike because there is no load against it at all. If you hit the bearing hard when fitting the bearings you will crack it, we have found out the hard way. The one in the video hasn’t had a problem after 7 thousand kms, which leaves me wondering why yours failed on its first ride since the modifcation. My one in the white bike cracked because the guy that assembled it (used to work for Nick) pressed the bearing in and cracked the retaining sleeve. The hub has been resleeved since (Metal sleeve) and returned to service on my bike. It did some 7k before the crack we saw on assembly actually broke away. No damage to anything else as I found it sitting out about 15mm and nursed it to town.

The others done like Wolfmans King Kenny Jnr etc have never caused a problem and his has done maybe 5 or 6 thousand since the mod was preformed and when I changed the tyres recently inspected the hub and the retaining sleeve all was fine no problems. Again I have to stress there is no thrust or pressure on the sleeve once assembled and care needs to be taken when seating the bearing. The mod we are doing has been done on 660Rs in NZ for ages with a tour company and there hasn’t been a reported failure yet but I will watch with interest now.

I must admit even in the excitement of racing with your mate I am shocked you didn’t feel or hear it as it has caused some damage.

If you are stuck for a hub give me a yell pls I have two I could frieght and loan if required champ.TB

July 8, 2013 at 10:57 pm #245774Hi TB, thanks for the quick response and very generous offer.

Mate I couldn’t believe I didn’t hear it and seriously I did not hear a thing. Not just me but the guy chasing me who was right on my arse for 20klms and the 4 other guys we overtook, no one heard anything.

I carefully checked all the work myself and carefully seated the bearings in as well and checked it again after seating the bearings. Nothing was visible at the time but there is always the chance of a hairline crack that went undetected.

I did the mod as I thought it was a great idea and would fix a known poor design issue with the cushdrive on the Tenere.

I copped plenty of sh!t from the other 13 guys on the ride (which I had organised), when I had to head home at lunch on the first day. There’s never a broken down KTM when you need one!

Mate I would love to take up the offer on a spare hub if you have one that you could sell or loan. Happy to pay all freight costs and any fees. Team Moto are saying 2 to 4 weeks but no guarentee and I could not find a used one for love or money.

I would love to go riding sooner.

Let me know how you would like to go about it.

Dave

July 8, 2013 at 11:28 pm #245777No problem Dave give me a call and we will sort something out

0499 089715

TB

July 9, 2013 at 2:13 am #236650All I can say is bugger! :ohmy: And I need to buy some of those cable ties!

July 9, 2013 at 3:34 am #245781Bugger would have been having trailer it home, being able to ride it home was a real bonus.

Bunnings jtb, 7.6mm x 370mm and I also carry 4.8mm x 370mm. The packet they come in fits inside your camelbak bladder area.

I never go on a decent ride without at least 25 of each.

When my headlight support bracket broke through top and bottom in Glen Innes earlier this year, they held everything in place and got me home again.

July 9, 2013 at 12:14 pm #236651I’ve carried about 5 at most over the years… only 3 these days :ohmy: seeing the things you’ve used them on, and seeing as I’m a thrifty Ten owner I better get some :whistle:

I’m away with wife and kidlets, so viewing/doing this via phone… but is there any chance of some more shots of your adapter plate ‘thingo’ for your front guard? In the coming weeks I’m trying to mount a YZF guard on my Ten.

Thanks

-

AuthorPosts

You must be logged in to reply to this topic.